MACHINERY

22 different machines compose our industrial equipment ready for any customer request.

- Tube bending CNC 4 beam (Ø max 85 mm)

- Tube bending CNC 2 beam (Ø max 42 mm)

- Tube bending CNC 1 beam (Ø max 80 mm)

- Tube bending CNC 4 beam (Ø max 35 mm)

- Tube bending CNC 6 beam (Ø max 35 mm)

- Tube bending CNC planetary for bending reels/bobbins (Ø max 20 mm copper/alumin.)

- Two-headed,tube bender (Ø max 30 mm)

- Manual tube benders (Ø max 63-70 mm)

- Presses (max 35 tons)

- Axial rollblenders

- Bending machine CNC with 6 passages (Ø max 45 mm)

- Bending machine Pedrazzoli (Ø max 65 mm)

- Bending machine with 2 passages (Ø max 105 mm)

- Multi-head drilling machine

- Radial rollers for shaping tubing extremities ( sp. max 2 mm)

- Automatic disc cropper (max length 6 mt.)

- Cropper with manual disc

- Sanding machine

- Water-powered machine for hydraulic flexible drilling and squeezing

- Head tubing

- Milling machine

- Milling for tubing

Tool set

- Tangential hone

- Grinding machine for blade sharpening

- Traditional parallel lathe

- CNC milling machine

- Traditional milling machine

- Drilling machine

- Welding machine with continual wire

Measuring Instruments

- Tube bending CNC 4 beam (Ø max 85 mm)

- Three dimensional measuring bench

- Series of Johnson blocks

- Micrometers

- Comparator gauge

- Digital calliper to centesimal

- Gauge for carry-over thickness

- Optical comparator Prisms, parallel rectifying, etc.

- Fixed gauge for testing, bending, cutting, etc.

Ø

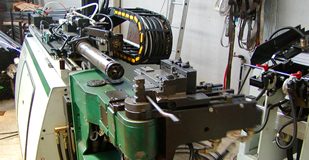

CRIPPA BECKHOFF

Over 22 different machines compose our industrial equipment ready for any customer request.

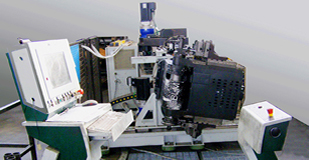

PEDRAZZOLI BEND MASTER

Over 22 different machines compose our industrial equipment ready for any customer request.

BLM E-TURN

Over 22 different machines compose our industrial equipment ready for any customer request.